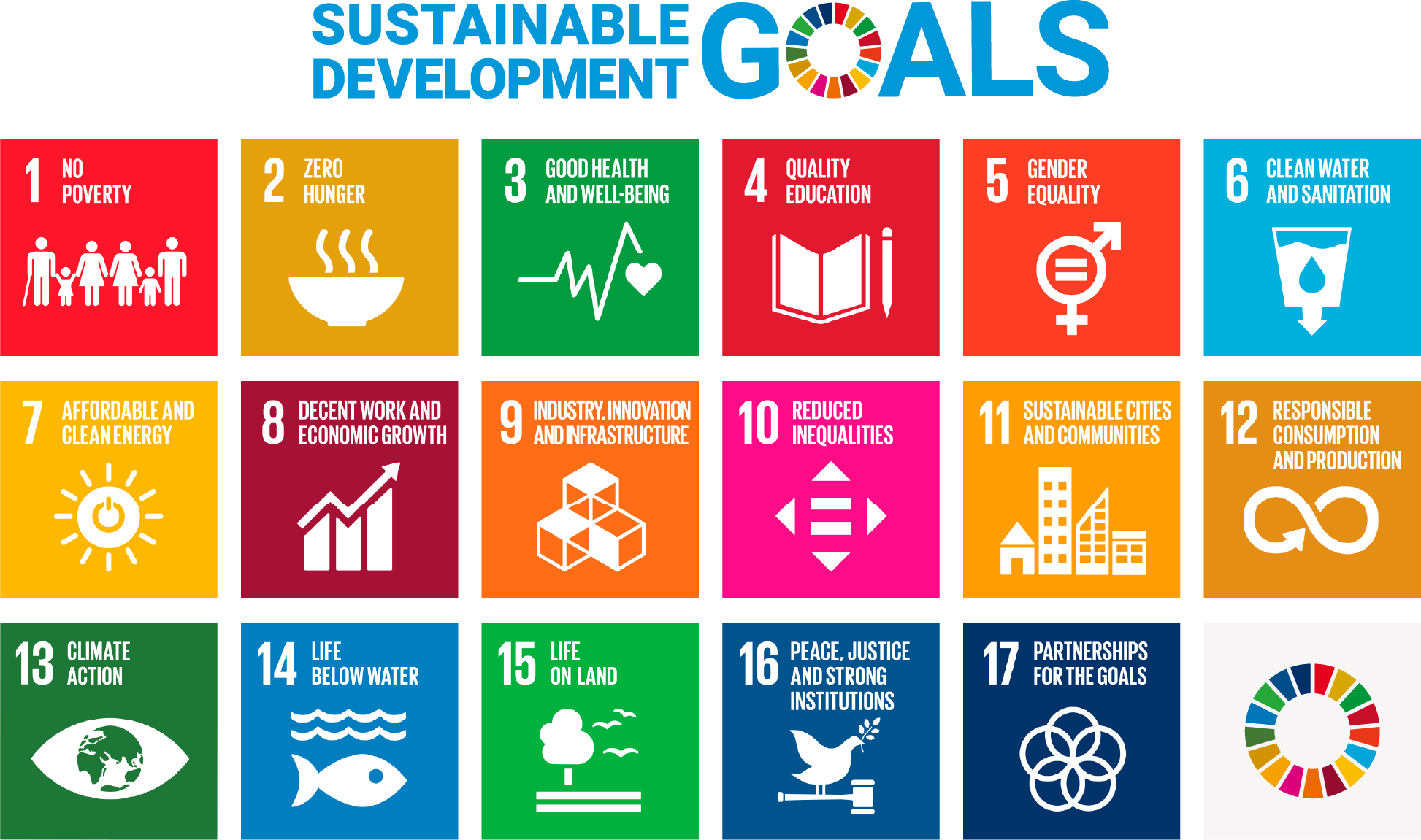

SDGs

About SDGs

SDGs is an abbreviation of "Sustainable Development Goals".

It is an international goal which aims for a sustainable and better world by 2030, and is stated in "2030 Agenda for Sustainable Development" adopted at the United Nations Summit in 2015. Composed of 17 goals and 169 targets, It pledges to "leave no one behind" on Earth.

FUJIOH's Main Efforts To Achieve SDGs

Based on the brand vision of "changing the air, changing the environment, to enrich tomorrow", FUJIOH is making efforts to achieve the SDGs through our business activities and activities around the business. We will continue to make various efforts towards the sustainable future.

| Corresponding SDGs Goals | Example Of Efforts | |

|---|---|---|

|

4.1 By 2030, ensure that all girls and boys complete free, equitable, and quality primary and secondary education leading to relevant and effective learning outcomes. 4.5 By 2030, eliminate gender disparities in education and ensure equal access to all levels of education and vocational training for the vulnerable, including persons with disabilities, indigenous peoples, and children in vulnerable situations. |

We provide learning support as volunteer staff at "Fuchinobe Learning School," which supports the learning of elementary to junior high school students with foreign parents. |

|

5.4 Recognize and evaluate unpaid childcare / nursing care and domestic work through the provision of public services, infrastructure and social security policies, and the division of responsibilities within households and families according to the circumstances of each country. | We are creating a comfortable working environment in Japan by implementing a work-at-home system, as well as childcare leave and nursing care leave, which allow employees to take longer leaves than mandated by law. |

|

6.4 By 2030, substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and supply of freshwater to address water scarcity and substantially reduce the number of people suffering from water scarcity. |

We contribute to water saving and improving the efficiency of water resources through the development, production, sales and promotion of cooker hood equipped with our original "OIL SMASHER" technology that can reduce the amount of water used for cleaning by about 70%* compared to the basic model (BDR-3HL) in Japan. *Based on our in-house calculation. Calculation based on Japan usage. |

|

7.3 By 2030, double the rate of improvement in energy efficiency worldwide. | We are working on the development of products that reduce environmental burden, such as recycling type cooker hoods that reduce air conditioning energy loss and cooker hood equipped with "OIL SMASHER" that saves water. The development and sale of these high value-added products also contributes to the improvement of economic productivity. |

|

8.2 Achieve a high economic productivity through diversification, technological improvement and innovation by focusing on high value-added sectors and labor-intensive sectors. |

|

| 8.5 By 2030, achieve full and productive employment while providing human suited work and equal pay for equal work for all men and women, including younger people and persons with disabilities. | We are committed to multinational hiring and employment of people with disabilities so that diverse human resources can work with their individual strengths. | |

|

11.7 By 2030, provide universal access to safe, inclusive, and accessible, green, and public spaces, in particular for women and children, older persons, and persons with disabilities. | We organize a monthly cleanup activities in the areas surrounding our business premises. At our Sagamihara headquarter, we actively participate in Sagamihara City's "Cleanup Sagamihara - Town Beautification Program" and actively involved in enhancing the environmental aesthetics of nearby parks. As integral members of the local community, we are committed to and will continue engaging in activities that contribute to sustainable city development and environmental conservation. |

|

12.5 By 2030, significantly reduce waste generation by preventing, reducing and reusing waste. | As a manufacturer, we are engaged in environmentally friendly production, such as recycling of waste materials and properly treating waste liquid. Furthermore, FUJIOH SHOP is actively contributing to waste reduction by offering outlet products. These items are products that may have incurred damage to their outer packaging during transportation or extended storage, leading to their classification as discarded. Through the sale of such outlet products, we aim to minimize waste and promote sustainable practices in our business operations. |

|

13.3 Improve education, awareness-raising and human and institutional capacity on climate change mitigation, adaptation, impact reduction and early warning. | We own a significant amount of equipment powered by LP gas. By transitioning the fuel used at our Sagamihara factory to town gas, we achieved zero SOx and dust emissions and reduced CO₂ and NOx emissions by 30-40%. In the case of recycling products, the reduction of air conditioning energy loss allows for a yearly decrease of 263kg* of CO₂ per unit. We aim to contribute to global warming countermeasures through the development, production, sales, and promotion of the "Recycling Cooker Hood." *Based on our in-house calculation. Calculated for the Tokyo area; actual usage environments may vary. |

|

14.1 By 2025, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution. | The wastewater released from our factory undergoes appropriate treatment utilizing specialized equipment to address pH levels, impurities, oil, heavy metals, and other components in compliance with the Water Pollution Control Act and the Sewerage Act. Moreover, we have established an internal target that is 10 to 20% more stringent than the legal standard, and we are meticulously overseeing the process to ensure that no harmful substances are discharged beyond the premises. |

|

12.5 By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse. | We are participating in the BRING UNIFORM* recycling project, where we collect and recycle work clothes that are no longer in use to reduce waste. *BRING UNIFORM recycles work clothes into recycled polyester and other materials, tailoring the process to suit each material. The ability to manufacture polyester anew contributes to a reduction in the amount of mined petroleum. |

|

13.3 Improve education, awareness-raising, and human and institutional capacity on climate change mitigation, adaptation, impact reduction, and early warning. | |

|

17.17 Encourage and promote effective public, public-private, and civil society partnerships, building on the experience and resourcing strategies of partnerships. | |

Back to the top page for more kitchen interior inspiration.